Thermotubix Aerospace, very high temperature and fire protection up to +1100°C

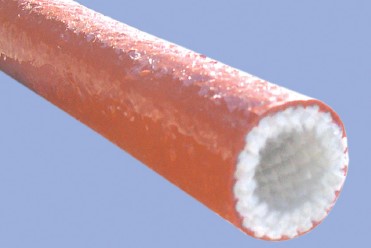

Fire and heat protection fiberglass braided and silicone rubber coated sleeve, EN-45545-2 approved, UL tested

Aerospace Thermotubix is a thickwall braided fiberglass sleeving coated with a specially compounded, flame retardant silicone rubber. This product can be easily installed on cables and hoses and expands to pass over fittings and couplings.

Aerospace Thermotubix offers an effective protection against sustained high temperatures, flames and molten metal splashes that can seriously damage electrical cables and hydraulic, gas and lubricant supply lines.

The construction of Thermotubix ensures an excellent fire protection for tubing up to +1100ºC (+2012°F) peak temperature according to SAE-ASTM specifications. This product provides thermal protection against internal and external hazards in a variety of industries, including aeronautics, naval, iron and steel, and automotive. There is also a coated fiberglass tape, called Thermobande available. This is used for the fire protection of tubing after the fitting of end terminations.

Product Facts of Thermotubix Aerospace

- Operating Temperature: -54°C to +260°C

- Fire Protection up to +1100°C / 15min. or +800°C / 30min.

- Flexibility to -54°C

- EN45545-2

- UL 73 tested, compliant with UL 181 Standards

- SAE 1055

| Dimensions in mm | ||||

| Part Number | Inside Diameter | Wall Thickness | NATO Specifications | Part Number |

| Thermotubix 8-12 | 8 | 4 | 5970-14-455-2318 | 4001000810F0100 |

| Thermotubix 9.5-12 | 9.5 | 4 | 5970-14-455-2322 | 4001001010F0100 |

| Thermotubix 12.7-12 | 12.7 | 4 | 5970-14-455-2324 | 4001001310F0100 |

| Thermotubix 16-12 | 16 | 4 | 5970-14-413-6212 | 4001001610F0100 |

| Thermotubix 19-12 | 19 | 4 | 5970-14-413-6213 | 4001001910F0100 |

| Thermotubix 22-12 | 22 | 4 | 5970-14-413-6214 | 4001002210F0100 |

| Thermotubix 25-12 | 25 | 4 | 5970-14-413-6215 | 4001002510F0050 |

| Thermotubix 32-12 | 32 | 4 | 5970-14-413-6216 | 4001003210F0050 |

| Thermotubix 38-12 | 38 | 4 | 5970-14-413-6217 | 4001003810F0050 |

| Thermotubix 45-12 | 45 | 4 | 5970-14-413-6220 | 4001004510F0030 |

| Thermotubix 51-12 | 51 | 4 | 5970-14-413-6221 | 4001005110F0030 |

| Thermotubix 57-12 | 57 | 4 | 5970-14-413-6222 | 4001005710F0030 |

| Thermotubix 64-12 | 64 | 4 | 5970-14-455-2328 | 4001006410F0020 |

| Thermotubix 76-12 | 76 | 4 | 5970-14-455-2331 | 4001007610F0020 |

| Thermotubix 89-12 | 89 | 4 | 5970-14-455-2332 | 4001008910F0020 |

| Thermotubix 101-12 | 101 | 4 | 5970-14-455-2334 | 4001010110F0020 |

| Property | Test Method | Result |

| Operating Temperature | -54°C to +260°C | |

| Low Temperature Flexibility | ASTM D-746 | -54°C |

| Flammability / Smoke / Toxicity | ASTM D-350, Methode B | Does not burn |

| NF 16101 - NF 16102 | I2 F0 | |

| DIN 5510-2 DB 54837 | S4, SR2, ST2 | |

| DIN EN ISO 5659-2 | CIT 8min : 0.036 ; FED 30min : 0.031 | |

| EN45545-2 | R22 HL3, R23 HL3 | |

| >64mm R9 HL3 | ||

| ASTM E 662 - ASTM E 162 | Pass | |

| SMP 800-C - BSS 7239 | Pass | |

| Fire Resistance | 15min at +1100°C | |

| 30min at +800°C | ||

| Fluid Resistance | 1 hour soak in Gasoline, Engine oil, Power Steering fluid, Transmission fluid, Coolant, Battery acid. | No cracking or degradation resulted from soak in any oft he tested fluid |