Heat shrink tube

What is a heat shrinking tube

Heat shrinkable tubes or thermofit tubes shrinks when exposed to heat and insulates underlying conductors and cables. Thanks to the radiation cross-linking an ordinary plastic tube is given shape memory. In this way, the tube does not melt away under the influence of heat, but returns to its original shape. Depending on the plastic (thermoplastics) used, the heat shrink tubing meets different requirements. Heat-shrink tubes can be used for electrical insulation, abrasion protection, moisture protection, colour coding, temperature protection, bundling, beautification and many other applications. Depending on your application you can choose from heat-shrinkable tubes that are semi rigid or highly flexible, designed for operation in high temperature or low temperature environments, low outgassing, medical approved, halogen-free and flame-retardant to meet a range of industry standards. Single wall tubes can be used for a wide range of applications. Or for moisture proof applications a dual-wall heat shrink tube with meltable inner layer made of adhesive. No matter what requirements you have, Raytronics AG finds the right tube for you.

At Raytronics AG, heat-shrink tubing is mainly divided into two different categories. Thin-walled heat-shrink tubing without adhesive and dual-walled heat-shrink tubing with an adhesive layer. Here are the two categories:

How exactly do heat shrink tubes work?

Two properties in particular helped the shrinkable tubing to achieve its breakthrough. The shape memory and the fact that radiation-crosslinked heat-shrink tubing does not melt. These properties are achieved through molecular crosslinking. Both properties are explained in more detail below:

How works the radiation crosslinking of heat shrinkable tubes?

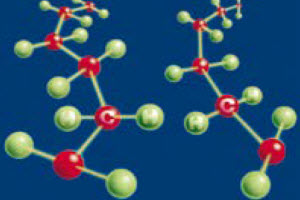

Molecular cross-linking prevents the heated shrink tube from flowing, melting and dripping. The irradiation of the plastic changes the molecular structure. The processes are explained in more detail here:

|

Termoplast consists of chain-like molecules. Between nearby molecule crystalline zones will form from one molecule chain to the other. These zones dissolve on heating above the crystalline melting point. For polyethylene, this temperature is around 120°C. When the crystalline zones dissolve, the plastic flows and melts. |

|

When researching thermoplastics and plastics, it was found that these materials change under the influence of high-energy electron beams. Hydrogen atoms split off during irradiation and create a chemical bond between neighboring molecules. |

|

With this molecular cross-linking of heat shrink tubing, a three-dimensional network is formed, whereby the radiation-crosslinked thermoplastics do not differ externally from conventional thermoplastics. However, as soon as the radiation-crosslinked thermoplastics are heated, they behave differently. The crystalline zones also dissolve, but the crosslinking points that hold the molecules together remain. As a result, the thermoplastic does not melt or flow. The plastic becomes elastic and behaves more like an elastomer (rubber). |

How does the shape memory of heat shrink tubing work?

Heat shrinkable tubes always returns to its original shape when exposed to heat. Heat shrinking tubes therefore has a so-called shape memory. How this works is described here:

|

| During the irradiation or molecular cross-linking of heat shrink tubing, cross-linking and chemical connections are created between the individual molecules. In Figure 1 you can see a section of cross-linked molecular chains. |

|

| As soon as a thermoplastic is heated above 120°C, the so-called crystalline zones are dissolved (orange dots in Figure 1). These are now missing in Figure 2. Without these crystalline zones, the plastic is elastic and can be expanded and stretched. |

|

| In the stretched and expanded state, the individual molecules are now only linked to one another by the cross-connections. |

|

| If the heat-shrinkable tubing is cooled down in the expanded state, the crystalline zones form again between the molecular chains and fix the tubing in the expanded state. If you order heat shrink tubing, you will receive the tubing in this condition. |

|

| As soon as the heat shrink tube is heated again for processing, the crystalline zones dissolve again. Thanks to the crosslinking power of molecular crosslinking, the tube retracts to its original diameter. This process is called elastic shape memory. |

|

| After processing, the heat shrink tube cools down again. The crystalline zones form again. The plastic and thus the entire shrink tube is fixed in its shrunken form. |

What sizes are available for heat shrinking tubes?

Heat shrinkable tubes comes in many different sizes. The standard sizes starts at 1.2mm by 0.6mm and ends at 38mm by 19mm. Please refer to the table below for the exact sizes. We can produce special sizes on request.

| 2 to 1 shrink ratio |

3 to 1 shrink ratio |

4 to 1 shrink ratio |

|

| Inch | Milimeter | Milimeter | Milimeter |

| 3/64 | 1.2/0.6 | 1.5/0.5 | 4/1 |

| 1/16 | 1.6/0.8 | 3/1 | 8/2 |

| 3/32 | 2.4/1.2 | 6/2 | 12/3 |

| 1/8 | 3.2/1.6 | 9/3 | 16/4 |

| 3/16 | 4.8/2.4 | 12/4 | 24/6 |

| 1/4 | 6.4/3.2 | 18/6 | 32/8 |

| 3/8 | 9.5/4.8 | 24/8 | 52/13 |

| 1/2 | 12.7/6.4 | 39/13 | |

| 3/4 | 19/9.5 | ||

| 1 | 25.4/12.7 | ||

| 1-1/4 | 31/16 | ||

| 1-1/2 | 38/19 | ||

| 2 | 51/25.4 | ||

| 3 | 76/38 | ||

| 4 | 102/51 | ||

How differs heat shrinkable tubes?

Besides to the different shrinking ratios (2 to 1, 3 to 1 and 4 to 1) and the subdivision into heat shrink tubing with adhesive, heat shrink tubing without adhesive and heat shrink tubing for medical applications, there are other differences. Raytronics AG also classifies heat shrinkable tubes according to colours, temperature ranges, materials and approvals.

What colours are available for heat shrink tubes?

Heat shrink tubes are available in many different colors. The standard colors are black and transparent. Especially for single wall heat shrinkable tubes without adhesive, Raytronics AG offers a large selection of different colors from stock. The following colors are available:

| Colour Code |

-x | -0 | -1 | -2 | -3 | -4 | -5 | -6 | -7 | -8 | -9 |

| Colour | Clear | Black | Brown | Red | Orange | Yellow | Green | Blue | Violett | Grey | White |

Welche Unterschiede gibt es bei den Temperaturen bei Schrumpfschläuchen?

Je nach Anwendung wird eine andere Temperaturbeständigkeit verlangt. So gibt es neben Schrumpfschläuchen für Standardanwendungen auch hochtemperaturfeste Schrumpfschläuche, die Temperaturen bis +260°C aushalten. Zur Überschrumpfung von temperatursensitiven Anwendungen oder PVC Kabeln, werden Schrumpfschläuche mit tiefen Betriebstemperaturen verwendet. Dafür wurden Schrumpfschläuche wie die LSTT-Serie entwickelt, die bei besonders tiefer Temperatur schrumpfen.

| Betriebstemperatur Schrumpfschläuche ohne Kleber | +105°C bis +135°C | +150°C bis +200°C | +205°C bis +260°C |

| Betriebstemperatur Schrumpfschläuche mit Kleber | bis +110°C | +125°C bis +150°C | über +150°C |

In welchen Materialien sind Schrumpfschläuche erhältlich?

Wärmeschrumpfende Schläuche sind ohne Kleberschicht in den Materialien Polyolefin, Polyolefin halogenfrei, Elastomer, Kynar, Fluoropolymer, FEP (Fluoroethylenpropylen), Teflon (PTFE und TFE), Viton und Silikon. Schrumpfschläuche mit Kleber gibt es aus Polyolefin, Polyolefin halogenfrei und FEP/PTFE (Dual-Schlauch).

Jedes Material hat unterschiedliche Eigenschaften und eignet sich daher für unterschiedliche Anwendungen.