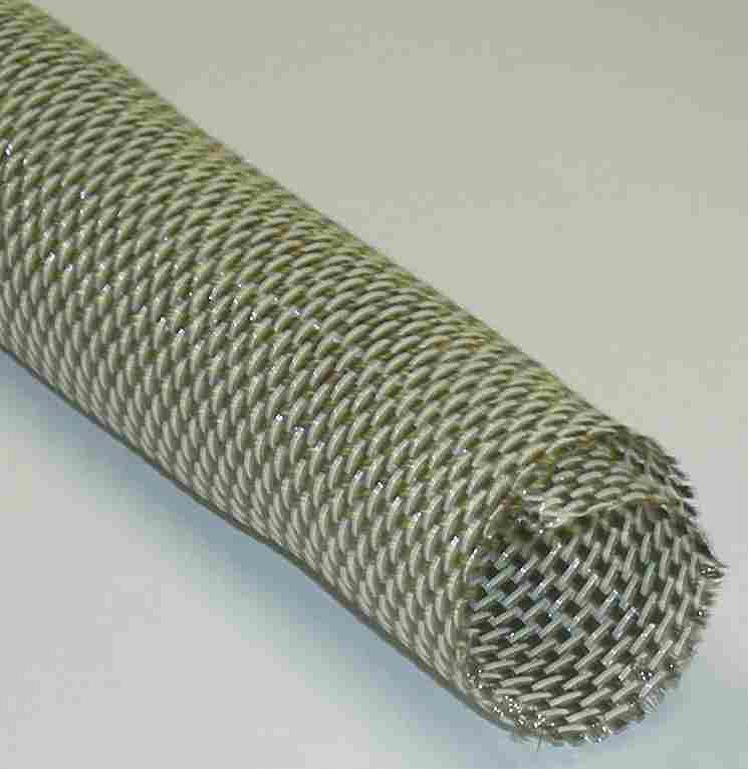

Roundit V0 EMI, wrap-around zero halogen EMI shielding

EN 45545-2 and halogen free self wrapping EMI braids for rail applications

ROUNDIT V0 EMI is a wrap-around sleeving designed for high performance EMI shielding of wire and cable bundles. ROUNDIT V0 EMI is manufactured from UL 94 V0 rated PPS monofilaments and nickel plated copper wires class 4 according to ASTM B-355. The self-wrapping feature of ROUNDIT V0 EMI allows for quick and easy installation and removal of the product for assembly and maintenance.

The design offers innovative solutions to the protection of breakout areas and also provides ease of removal when inspection or maintenance of cables is necessary. The stable construction guarantees the same level of EMI shielding regardless of the diameter on which it is installed within the recommended application range.

As an additional benefit, ROUNDIT V0 EMI enables users to stock a limited range of sizes to cover a wide range of cable and wire diameters. ROUNDIT V0 EMI has many applications in the railway, marine and electronics industries.

Product facts of Roundit V0 EMI

- High performance EMI shielding

- Halogen free

- EN 45545-2

- UL 94 V0 Raw Material

- ASTM E-162, ASTM E-662, BSS 7239, SMP 800-C

- Self-wrapping design

- Easy installation

- Ideal for reworking components without disconnecting them

| Dimensions in mm | ||||||

| Partnumber | Nom. Size | Rec. Application Range | Cross Section | Weight | ||

| Min. | Max. | mm2 | g/m | |||

| Roundit V0 EMI 8 | 5667500808S | 8 | 5 | 8 | 3.5 | 40 |

| Roundit V0 EMI 13 | 5667501308S | 13 | 8 | 13 | 4.8 | 55 |

| Roundit V0 EMI 19 | 5667501908S | 19 | 13 | 19 | 5.9 | 66 |

| Roundit V0 EMI 25 | 5667502508S | 25 | 19 | 25 | 6.9 | 80 |

| Roundit V0 EMI 32 | 5667503208S | 32 | 25 | 32 | 8.9 | 105 |

| Roundit V0 EMI 38 | 5667503808S | 38 | 32 | 38 | 10.6 | 120 |

| Roundit V0 EMI 45 | 5667504508S | 45 | 38 | 45 | 11.9 | 140 |

| Property | Test Method | Result |

| Operating Temperature Range | -50°C to +200°C | |

| Heat Aging | EN6059-302 (168 hours) | +200°C |

| Fire / Smoke / Toxicity | UL 94 | Raw Material classified V0 |

| BS6853 | Zero Halogen | |

| EN 45545-2 | R22 HL3, R23 HL3 | |

| DB DIN 5510 § 2 & 54837 | S4, SR2, ST2 | |

| SMP 800-C - BSS 7239 | Pass | |

| ASTM E 662 - ASTM E 162 | Pass | |

| EMI Performance | IEC 62153-4-3 | Lt = 1.2 nH |

| EN 3475-301 | R0 max all sizes = 6 mΩ | |

| Fluid Resistance | EN 6059-309 | No visiblie degradation |

| - Hydraulic Fluids (NATO.0.156) | Immersion for 24h at +70°C |