Solder devices

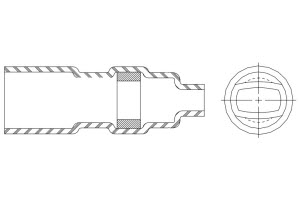

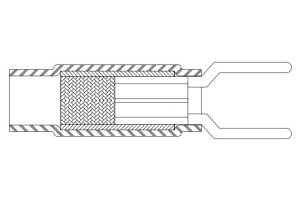

Solder Sleeves and Solder Devices

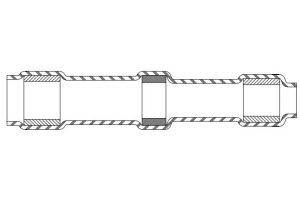

Solder sleeves and solder devices are designed to offer an easy one-step soluton for wire connections to tabs, posts, pins and mass wire terminations. These wire temination products are housed in a transparent heat shrink insulation sleeve, which provide inspectability and can provide various levels of environmental protection. The fluxed solder preform is essential for a highly controlled soldering process of TE Connectivity (Raychem) solder sleeves. If you are looking for high-quality electrical and mechanical performance, TE's Solder Devices are your fist choice.

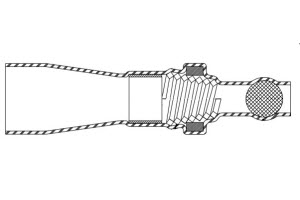

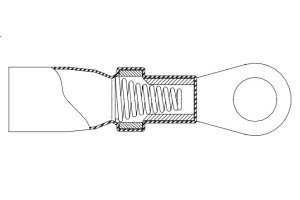

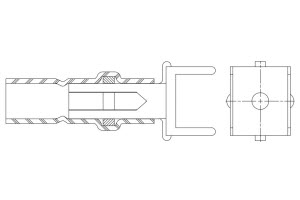

How does Solder Sleeves and Solder Devices work?

After heating the premeasured solder and flux inside the heat shrink sleeve melts and creates a repeatable and reliable termination. The heat shrinking tube shrinks and provides a fully insulated, strain-relieved and protected connection. The solder devices help reducing inventory and installation costs, provides a strong and controlled connection and due to the transparent insulation sleeve an easy inspection of the connection.

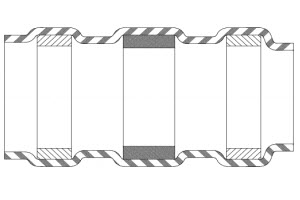

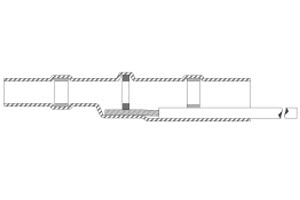

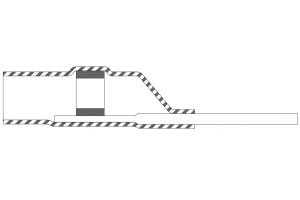

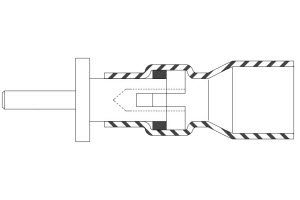

Solder Sleeves with two sealing rings

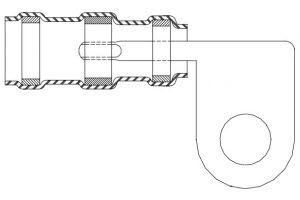

SolderSleeve Wire Splices

These Solder Sleeves are designed for wire-to-wire connections. Made from transparent polyvinylidene fluoride or polyolefin these wire splices provides encapsulation, inspectability, strain relief and insulation. Due to the prefluxed solder perform the solder sleeves from TE Connectivity (Raychem) provides a controlled soldering process. The unique one-piece desing makes the installation easy and lowers the installation costs. The two sealing rings at each end of the sleeves provids a better sealing to environmental influences.

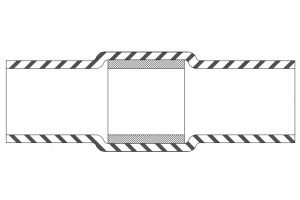

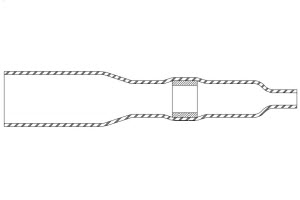

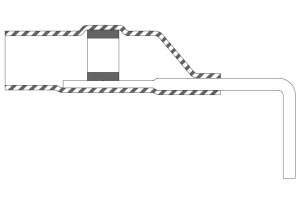

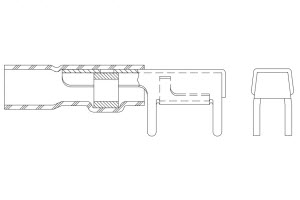

Solder Sleeves RoHS, lead-free

Lead-Free RoHS Solder Sleeves

Like other solder sleeves and wire-to-wire splices these parts are designet to solder, encapsulate, strain-relieve and insulate. These types of solder sleeves here from TE Connectivity (Raychem) are made of lead-free solder. Thanks to the solder type SN96 these solder sleeves complies with RoHS requirements. Please choose from the following four different types of lead-free soldersleeves.